Zirconium silicate

Because of its low thermal expansion coefficients and high thermal shock resistance, zircon (zirconium silicate) finds widespread use in the ceramic foundry, refractory industries, and as an opacifier in ceramic industry.

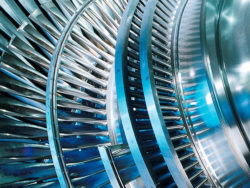

Zircon is the primary mineral resource for the production of zirconium metal (Zr) and zirconia (ZrO2). Zirconia is one of the most refractory substances known and is the basis of a variety of advanced ceramic materials ranging from high ionic conductivity to high mechanical strength and toughness (see jet engine blades).

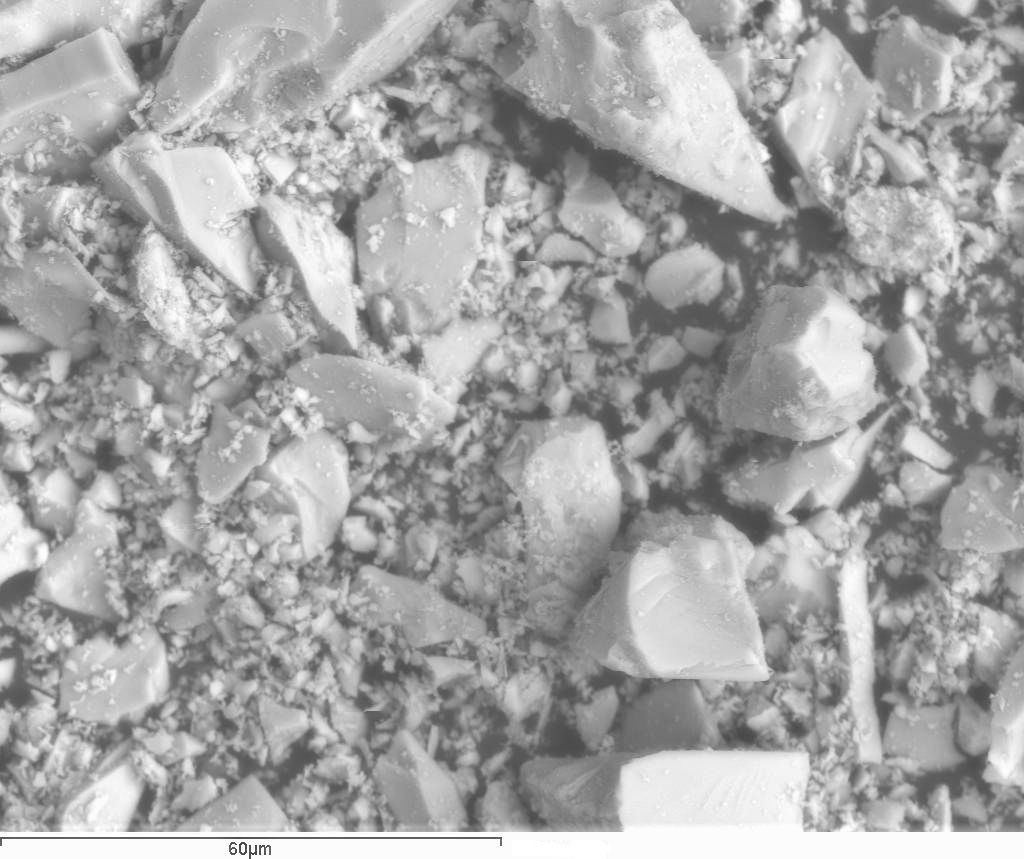

Zircon sand is milled up to achieve the desired size distribution. A scanning electron image of zircon flour with particles below 75 micrometers. is shown below.

APPLICATIONS